Every manufacturer focuses on improving productivity. That's why figuring out how to increase productivity in manufacturing company has brought about lean manufacturing strategies which continue to gain popularity.

Companies are constantly looking to minimize downtime, maximize operational efficiencies, and reduce costs to efficiently improve manufacturing. What some manufacturers fail to understand, though, is that productivity can only be as good as your equipment.

How to Increase Productivity in a Manufacturing Company

Production managers everywhere are being asked to make do – and make more — with less. Less resources, less maintenance time, less skilled help.

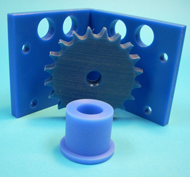

While this is certainly a challenge for anyone working on a shop floor, there is one major tip that can help maximize efficiency while minimizing maintenance and downtime – use plastic components in your manufacturing, processing, assembly, and distribution systems.

Why High-Performance Plastics Improve Manufacturing Processes

Did you know nothing resists wear, corrosion and chemicals quite like plastics? This is because plastic is:

1. Durable and extremely impact- and wear-resistant

This makes it ideal for high-speed, high-volume operations such as conveyor systems.

2. Chemical and corrosion-resistant

So, plastic withstands rigorous cleaning for food and pharmaceutical manufacturing operations. Plastic can never rust.

3. Economical

Plastics require less fuel and less lubrication to operate because machinery utilizing lighter plastic parts reduce friction and are more efficient.

4. Safer

This is because high-performance plastic equipment can utilize one-piece construction, smoother edges, and less risk of injury or damage from heavy, sharp, or flying pieces in case of equipment malfunction.

High-performance plastic components and systems made from a variety of plastics are FDA compliant. Compliant metal detectable plastics enable the detection of metal in food and pharmaceutical products, providing greater safety and reliability while reducing the risk of contamination and costly product recalls.

If you’re a discrete or process manufacturer operating in a tough production environment, upgrading your systems with high-performance plastic components can help you avoid a serious loss of time and money.

Conveyor systems used in production and material-handling facilities benefit from high-performance plastic components because they offer significantly less wear; faster, more reliable performance; less noise; and less required lubrication. All of this adds up to less maintenance downtime, greater throughput, and overall increased productivity.

Productivity can only be as good as your equipment, and equipment made from high-quality plastic components is as good as it gets.